A number of you have asked that I share more of my knowledge / experiences, so, as a Thank You for sharing your knowledge - Here Goes!

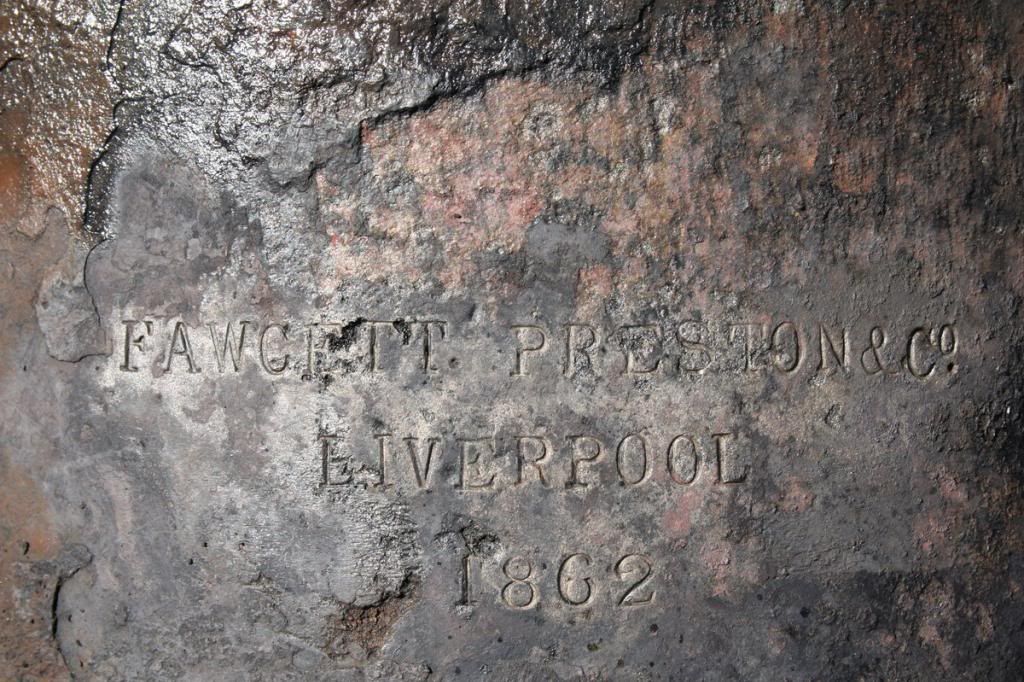

The Lab was asked sometime ago, to clean and conserve a 6" Fawcett & Preston Smoothbore from the wreck of the CSS Alabama. Sure, why not, I am after all a good Southern Boy - from South Africa. As a kid, I grew up learning an English ditty (a song!) - Here comes the Alabama. The vessel visited Cape Town in 1863, and was warmly welcomed by the locals. BTW, did you know that Raphael Semmes VI graduated from Texas A&M University in ~ 2005. It is a small world we live in!

Anyway, the cannon arrived and we cleaned the outer concretion off the cast iron, using a variety of techniques include careful use of a ballpeen hammer, airscribes, etc.

We then had to run it through a series of electrolytic baths, to remove the chlorides, and reduce the iron to a more stable state. So one needs a slightly larger ER vat, about 900 gallons, as the cannon is ~ 9' long and weights ~ 6,000 lbs. If I recall correctly, she was in ER for over two years.

Periodically, we took the cannon out and continued the finer mechanical cleaning. We had to drill out the bore, as it too was filled with concretion. Surprisingly enough, "they" do not make hollow core drill bits the correct size. Off to see a friendly machinist, who made us the necessary bit, along with the 1" diameter shaft. This was inserted into the bore, and rotated with two 36" pipe wrenches, whilst a third person applied the "impact" with a 12 lb sledge hammer. Well, when we got down about 2 feet, I was asked - "What is that little round shiney thing down there?"

Okay guys, this is something we do at the Lab - do not do this at home! I will admit here that the cannon was at a 30 degree angle, and the bore was filled with water whilst we were drilling. Also, we were looking at a spherical shell with a time fuZe (Sp - I have been corrected here), that needs an ignition source. So we carried on diligently, and drilled down to the shell.

Now, some of you may know that if you place blackpowder in a cast iron container, and seal it up for 100 years - with some moisture, you will not have gunpowder when you re-open the container. Our shell had been underwater for ~ 140 years, so had losts of moisture, which alters the chemical composition completely. One of the new components is hydogen sulfide gas, which is both flammable and explosive. So one has to be very careful here, as one potentially has a shell filled with explosive gas, and one ALSO has to remember that there is the remains of the powder bag behind the shell, which will also be under pressure with explosive gas. We used a stainless steel chisel, to carefully cracked the concretion between the shell and the bore, about 1/8" all around - think windage. The cannon barrel was still at an angle, filled with water. We were working outside, and had a high pressure fan going to dissapate any escaping gas. Well, when we made the break, there was a roar like a freight train and ~ 10 gallons of water exited the barrel coating way too many people (and even more onlookers !). Yeah Right, think safety here, they all wanted to be there to see the explosion. A water hose was quickly applied, to keep things wet. The fan took care of the gas, I have never liked rotten eggs! We then oriented the barrel downwards, and slid a piece of sheet metal under the shell, and carefully pulled it out, along with the sabot. Sadly, the powder bag had disintegrated, and all that remained were the "ribbons" used to tie the bag closed. The fuze was a simple Water Cap time fuze, sorry but I cannot seem to find a photo.

Sights, I was asked to post a few images. Here is a view looking down the barrel. Sadly, the iron tip to the front site did not survice. The sights are numbered with the serial number of the cannon, as they are calibrated at the proofing range.

When you look at this image, I want you to think Point Blank Range - 400 yards. This is where the sights were set when the cannon was last fired off Cherbourgh, France, by Englishmen from Liverpool.

This is an image from the top of the barrel.

This is what she looked like, before we crated her up and shipped her off to the US Navy.

Thanks guys, hoped you liked a bit of History.

Jim J.